Turkey has emerged as a strategic hub for global apparel manufacturing, offering a unique blend of geographical advantage, skilled labor, and modern infrastructure. As global markets evolve, Turkey’s textile sector continues to adapt, embracing new technologies, sustainability efforts, and shifting consumer demands. Below, we explore the most impactful trends transforming the Turkish apparel manufacturing industry, helping businesses stay competitive in a dynamic global economy.

1. Digital Transformation and Smart Manufacturing

The integration of Industry 4.0 technologies is redefining the operational backbone of Turkey’s apparel factories. From AI-driven production planning to IoT-enabled machinery, Turkish manufacturers are modernizing rapidly to optimize efficiency, reduce waste, and improve quality control.

Key Developments:

- Computerized cutting systems reduce fabric waste by up to 30%.

- Automated sewing technologies increase output consistency and speed.

- Predictive maintenance using IoT sensors ensures minimal downtime.

- Digital twin simulations are being used to model factory processes before execution.

Turkish manufacturers leveraging these innovations are better positioned to meet tight deadlines, reduce costs, and compete globally.

Suggested Visual: Infographic comparing traditional vs. smart apparel manufacturing processes.

2. Sustainable and Eco-Friendly Production Practices

As global fashion brands adopt stricter environmental standards, Turkey’s apparel manufacturers are embracing sustainable practices to remain compliant and attractive to eco-conscious buyers.

Sustainability Initiatives Include:

- Recycled fabric usage, including GRS-certified cotton and polyester.

- Water-saving dyeing technologies, reducing water usage by up to 90%.

- Solar-powered facilities that decrease carbon footprints.

- Closed-loop production systems that reuse water and energy.

Turkey’s commitment to environmentally responsible apparel manufacturing is helping build long-term trust with international clients and partners.

Suggested Visual: A photo of a Turkish factory with solar panels and eco-certifications displayed.

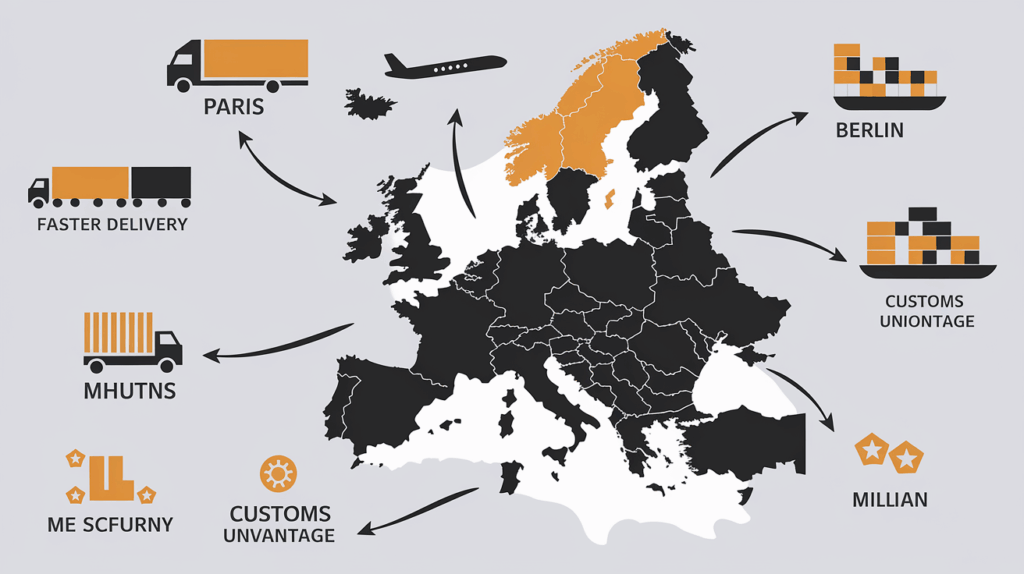

3. Nearshoring and Geographic Advantage for European Markets

Turkey’s proximity to Europe, coupled with its Customs Union agreement with the EU, makes it a preferred nearshoring destination for fast fashion and private label brands looking to reduce lead times and shipping costs.

Advantages of Nearshoring in Turkey:

- 4–6 week faster delivery times compared to Asian competitors.

- Reduced logistical risk and transportation expenses.

- Improved communication due to shared time zones and cultural familiarity.

- Duty-free access for many European clients.

Global fashion giants are increasingly shifting production from Asia to Turkey to meet consumer demand for speed, flexibility, and ethical sourcing.

4. Rising Investment in Research and Development (R&D)

To stay ahead in the competitive global apparel market, Turkey’s manufacturers are investing in textile R&D centers focused on fabric innovation, sustainable materials, and functional apparel.

Innovative R&D Focus Areas:

- Anti-bacterial and UV-resistant fabrics.

- Biodegradable and compostable textiles.

- Smart wearables with integrated sensors.

- Color-changing materials for fashion and utility.

This focus on continuous product innovation helps Turkish firms add value beyond low-cost production, appealing to high-end and technical clothing markets.

5. Workforce Development and Vocational Training

A cornerstone of Turkey’s apparel industry success lies in its highly skilled workforce. To meet growing demand and evolving technology, the sector is investing in vocational training programs and partnerships with universities.

Notable Initiatives:

- Public-private collaboration programs in textile engineering.

- Digital upskilling courses for machine operators and designers.

- On-site apprenticeships within large manufacturing hubs.

- Women-focused initiatives to increase gender parity in the workforce.

An agile and well-trained labor force ensures consistency in quality, quicker adaptation to innovations, and improved client satisfaction.

6. Demand for Private Label and Custom Apparel Solutions

With fashion brands seeking unique product lines, Turkish manufacturers are experiencing a surge in private label and custom production requests.

Private Label Trends:

- Smaller MOQs (Minimum Order Quantities) enable startup brands to scale.

- Rapid prototyping and sampling speeds up design validation.

- ODM/OEM capabilities allow seamless brand integration and manufacturing.

Turkey’s agility in offering tailored manufacturing solutions gives it an edge in a market driven by personalization and fast fashion.

Suggested Visual: Factory floor with branded apparel lines from different international clients.

7. Compliance with International Quality and Ethical Standards

To compete globally, Turkish apparel exporters are investing heavily in compliance with major international certifications to meet the expectations of global buyers.

Certifications Commonly Held:

- OEKO-TEX® Standard 100

- GOTS (Global Organic Textile Standard)

- BSCI (Business Social Compliance Initiative)

- ISO 9001 and ISO 14001

These certifications signify Turkey’s commitment to quality, worker safety, and environmental responsibility, making it a trusted partner for ethical apparel sourcing.

8. Expansion into Technical and Functional Apparel Segments

Beyond fashion, Turkey is gaining recognition in technical textile and performance apparel production, particularly in sportswear, medical textiles, and industrial uniforms.

Growth Areas Include:

- Moisture-wicking, breathable sportswear for global brands.

- Flame-retardant and high-visibility garments for safety industries.

- Compression wear and orthopedic textiles in medical sectors.

By tapping into these high-demand segments, Turkey diversifies its export portfolio and insulates itself from fashion market fluctuations.

9. Rise of E-Commerce and DTC (Direct-to-Consumer) Fulfillment

The global surge in e-commerce apparel sales has reshaped buyer expectations. Turkish manufacturers are now offering integrated e-commerce fulfillment services, including inventory management, drop shipping, and B2C packaging.

Capabilities Supporting E-Commerce Growth:

- Real-time order tracking systems

- Custom packaging and labeling solutions

- Seamless B2C logistics integration

This evolution enables manufacturers to cater not only to brands but also to independent e-commerce entrepreneurs and influencers launching their own lines.

Suggested Visual: Flowchart of a DTC apparel fulfillment pipeline from factory to doorstep.

10. Government Incentives and Export Support

Turkey’s government actively supports the textile sector through export incentives, tax reliefs, and financial aid programs for sustainable and digital transformation projects.

Key Support Mechanisms:

- KOSGEB grants for SME modernization.

- TURQUALITY® branding support for global expansion.

- R&D and innovation funding through TUBITAK programs.

- Low-interest export credits via Eximbank.

These initiatives reduce barriers for manufacturers to scale production, adopt new technologies, and penetrate new markets.

Conclusion: Turkey’s Apparel Manufacturing Industry is Poised for Global Leadership

Turkey’s apparel manufacturing sector is not only adapting to modern market demands but is also leading with innovation, sustainability, and responsiveness. With continued investments in technology, workforce, and infrastructure, Turkish manufacturers are positioning themselves as world-class partners for brands across fashion, performance, and technical segments.

The strategic combination of proximity to European markets, robust compliance standards, and diversified production capabilities makes Turkey a powerful player in the global textile landscape. For brands seeking ethical, efficient, and forward-thinking manufacturing, Turkey is the future.